Yakanakisa Yemotokari Welding Fixture Mugadziri uye Fekitori muChina

Company Development

- Muna 2011, TTM yakavambwa muShenzhen.

- Muna 2012, Kuenda kuDongGuan;Kuvaka hukama hwekudyidzana neMagna International Inc.

- Muna 2013 Kusuma zvimwe zvemhando yepamusoro midziyo.

- Muna 2016, Yakaunza yakakura-chiyero CMM michina uye 5 axis CNC midziyo;Yakabatana neOEM Ford Yakapedzwa Porsche, Lamborghini uye Tesla CF mapurojekiti.

- Muna 2017, Kuenda kunzvimbo yazvino yekudyara;CNC yakawedzerwa kubva pa8 kusvika ku17 seti.Yepamusoro Talent Automotive Fixtures & Jigs Co.Ltd yakavambwa

- Muna 2018, Yakabatana neLEVDEO mota uye yakapedza mutsara wekugadzira mota.4-axis yakakwira-kumhanya CNC yakaunzwa, iyo yakazara Qty yeCNC yakasvika makumi maviri nerimwe.

- Muna 2019, Dongguan Hong Xing Tool & Die Manufacturer Co., Ltd yakavambwa.(One stop sevhisi) Yakabatana naTesla Shanghai neSodecia Germany.Vakavaka rabhoritari itsva yeR&D yeotomatiki.

- Muna 2020, Yakabatana neOEM ISUZU muSA; Yakapedza iyo RG06 One-Stop Service.

- Muna 2021, Kufambira mberi nekutenda kwemhando yekugadzira bhizinesi repasi rose.

- Muna 2022, TTM Group hofisi yakavambwa muDongguan Guta, New CNC 4 axis * 5 seti, New Press * 630 matani, Hexagon Absolute Arm.

- Muna 2023, TTM iri kuvaka chirimwa chitsva chekutarisa zvigadziriso uye welding bhizinesi rekugadzirisa;kuwedzera imwe 2000T press.

Kutarisa Fixture & Welding Jigs Factory (Yakazara nzvimbo: 9000m²)

Kutsika Zvishandiso & Inofa uye Yakagadzirwa Zvikamu Factory (Yakazara nzvimbo: 16000m²)

Products Description

| Product Name | Welding Fixture |

| Application | Motokari CCB, Front End, WS Spring Link, Front Bumper etc. |

| Welding Type | Spot Welding, Arc welding, (CNC/Assembly) Special welding fixture |

| Pneumatic Component Brand | SMC, FESTO, TUENKERS, CKD, Manual clamp |

| Electrical Component Brand | OMRON, Mitsubishi, Siemens, Baluff |

| Chishandiso(Block, Pini Yekutsvaga) | 45# Simbi, Copper, Stainless Simbi |

| Operation Way | Robhoti Welding, Manual Welding, Special muchina welding |

| Kudzora Nzira | Mhepo Kudzora (Pneumatic Control Valve), Magetsi Kudzora(Solenoid Vhuru), Manual, Hapana solenoid vharafu inodiwa Ipa yekubatanidza switch |

| Clamping Way | Pneumatic, Manual |

| Kukurukurirana Nzira NeWelding Cell | EtherCAT, PROFINET, CC-LINK |

| Kukurukurirana Relay Bhokisi | Magetsi bhokisi wiring nzira, Kurumidza socket mhando, Solenoid valve chitsuwa mhando |

| Welding Fixture Base Type | Yakagadziriswa pasi, Positioner/Flip Tye |

| Piping Way | Single layer chubhu, Flame retardant chubhu, Copper/Stainless Simbi Tube |

| Fixture Surface Treatment | Painting, Painting+Black Oxidization, Zinc-Coated, Powder Painting |

| Nguva Yekutungamira | 2-4 Vhiki dzekugadzira uye dhizaini yekuongorora; 10-12 mavhiki ekugadzira mushure mekugadzirwa kwemvumo 7-10 Mazuva ekushanda kwekutumira mhepo; 4-5 Vhiki dzemvura yegungwa |

| Kufa Upenyu | Zvinoenderana nekugadzirwa kwemutengi |

| Quality Inishuwarenzi | CMM Kuongorora Edzai nemaSamples Onsite Buy-Off Vhidhiyo yepamhepo Webhu Musangano Buy-Off Buy-Off Matambudziko Kugadzirisa |

| Package | Mabhokisi emapuranga emasampuli; Mabhokisi emapuranga kana Pallets ekugadzirisa; |

Automotivewelding zvigadzirisondiwo maturusi akakosha mukugadzira mota.Izvi zvigadziriso zvehunyanzvi zvakagadzirirwa kuve nechokwadi chakanyatso kurongeka uye kusangana kwezvakasiyana zvikamu, kufambisa simbi yechasi, mapaneru emuviri, uye zvimwe zvikamu zvakakosha.Mukutarisa kwakazara uku, isu tichaongorora zvakakosha zvemotokari welding zvigadziriso, zvinosanganisira kukosha kwazvo, dhizaini kufunga, kugadzirwa, kutonga kwemhando, uye basa ravo muindasitiri yemotokari.1. Kukosha kweMotokari Welding Fixtures:

Zvigadziriso zveMotokari zvewelding zvinoita basa rakakosha mukugadzirwa kwemota nekuda kwezvikonzero zvakati: Kurongeka: Vanoona kurongeka chaiko kwezvikamu, zvichitungamira kune anowirirana uye akakwana welds.Izvi zvakakosha kune kurongeka kwechimiro uye kuchengetedzwa kwemotokari.

Kubudirira: Zvigadziriso zveWelding zvinomhanyisa maitiro egungano, kuderedza nguva yekugadzira uye mutengo wevashandi.Hunhu Simbiso: Nekubata zvikamu munzvimbo dzakaringana, zvigadziriso zvinoderedza njodzi yekukanganisa uye hurema muchigadzirwa chekupedzisira.Consistency: Fixtures inopa mhedzisiro inowirirana, zvisinei nehunyanzvi hwemushandisi, izvo zvakakosha kuti uwane yunifomu yemhando yemotokari.2. Dhizaini Kufunga: Kugadzira mota welding zvigadziriso inzira yakaoma iyo inosanganisira kunyatso tarisisa zvinhu zvakasiyana-siyana: Mota yeMotokari: Iyo dhizaini yedhizaini inofanirwa kuenderana neyakagadzirwa uye modhi yemotokari iri kugadzirwa.Izvi zvinoda kunzwisiswa kwakadzama kwezvinodiwa neungano yemotokari.Chikamu Positioning: Iyo gadziriso inofanirwa kunyatso kumisa zvinhu zvakasiyana-siyana zvemotokari, senge mapaneru emuviri, chassis zvikamu, uye furemu zvikamu.Izvi zvinosanganisira mapoinzi chaiwo enzvimbo, nzira dzekusunga, uye zvimiro zvekutsigira.Kushivirira uye Kurongeka: Mainjiniya anofanirwa kufunga kushivirira kwakasimba uye kurongeka zvinodiwa kuti ive nechokwadi chekuti zvikamu zvinokwana pamwechete zvakakwana.

Kusarudzwa Kwezvinhu: Sarudzo yezvishandiso zvekugadzirisa kwakakosha.Inofanira kuva yakasimba, isingadziviriri kupisa, uye yakasimba kuti imirire nzira yewelding.Ergonomics: Zvigadziriso zvinofanirwa kugadzirwa kuti zvive nyore kushandisa uye kuchengetedzwa kwevashandisi.Izvi zvinosanganisira kufunga kwekuwana, kuoneka, uye ergonomics panguva yekushanda kwewelding.3. Fixture Fabrication:

Kugadzirwa kwezvigadziriso zvemotokari welding kunosanganisira matanho akati wandei:

CAD Dhizaini: Vagadziri vanogadzira yakatsanangurwa 3D CAD modhi yechigadziriso, ichitsanangura chinzvimbo, kutarisisa, uye mapoinzi ekusungirira echimwe nechimwe chikamu.Kusarudzwa Kwezvinhu: Zvichienderana nemaitiro ekugadzira, zvigadzirwa zvakakodzera, kazhinji simbi kana aluminium, zvinosarudzwa pakuvaka kwechigadziriso.Component Manufacturing: Zvikamu zvega, zvinosanganisira zvimiro zvekutsigira, zvisungo, uye zvinhu zvekuisa, zvinogadzirwa nemazvo uchishandisa CNC machining uye humwe hunyanzvi hunyanzvi.Welding uye Gungano: Unyanzvi welders uye technician vanounganidza zvikamu, vachiva nechokwadi chokuti zvinopindirana pamwe chete zvakarurama uye zvakachengeteka.Muedzo: Iyo gadziriso inoedzwa kwakasimba kuti ive nechokwadi chekuti inosangana nekumisikidza uye kushivirira kunodiwa pakushongedza chaiko.Izvi zvinosanganisira kuyedza kuiswa kwezvikamu zvemotokari.Calibration: Iyo gadziriso inogadziriswa kuti ive nechokwadi chekuti inoramba iri mukurongeka kwakaringana uye inochengeta kuvimbika kwayo kwechimiro.4. Kudzora Kwehutano: Kuchengetedza maitiro emhando yepamusoro mukati mekugadzirisa kwekugadzirisa kunokosha: Kuongorora: Kuongororwa nguva dzose kunoitwa kuti kuve nechokwadi chekururama, kusimba, uye kushanda kwezvikamu zvekugadzirisa.

Kushivirira Macheki: Chaiyo kuyerwa uye kushivirira cheki kunoitwa kuratidza kuti chigadziriso chinosangana nezvinodiwa.

Alignment Verification: Fixtures inosimbiswa kuti ive nechokwadi chekuti inochengetedza kurongeka kwakaringana uye kutaridzika kwegungano.5. Basa muIndasitiri yeMotokari: Zvigadziriso zvemotokari zvinosungirirwa zvakabatanidzwa kune nzira yekugadzira motokari: Chassis Welding: Fixtures inovimbisa kurongeka kwakarurama kwezvikamu zvechasi, kusanganisira zvikamu zvefuremu uye zvigadziriswe.Body Panel Welding: Ivo vanobata mapaneru emuviri, senge magonhi, mahodhi, uye mafender, munzvimbo dzakaringana dzewelding, zvichibatsira mukurongeka kwese kwemotokari.Seam Welding: Fixtures anoshandiswa muwelding ye seams, majoini, uye zvinongedzo kugadzira zvisungo zvakasimba uye zvakavimbika.

Welding otomatiki: Muzviitiko zvakawanda, zvigadziriso zvewelding zvinosanganiswa nerobhoti welding maseru ekugadzira otomatiki, zvichiwedzera kuvandudza kushanda nesimba uye kuenderana.6. Kugadziriswa kweVagadziri veMotokari: Vagadziri vezvigadziriso zvemotokari vanowanzoita hunyanzvi mukugadzira zvigadziriso zvetsika zvakagadzirirwa kune zvakasiyana zvinodikanwa zvevagadziri vemotokari.Izvi zvigadziriso zvakagadzirirwa kusangana neindasitiri-chaiwo zviyero uye zvinodiwa, uye zvinogona kuchinjirwa kune akasiyana mota mota mukati memutsetse wechigadzirwa.Mukupedzisa, mota welding zvigadziriso chinhu chakakosha chekugadzira mota.

Solutions(Turnkey Solutions Service)

Body In White Assembly Systems:

1, Yakazara Mota Muviri Welding Line

2, Single Stand-egaWelding Cell

CCB ASSYWelding Fixture, Floor Pan ASSY Welding Fixture, Wheelhouse ASSY Welding Fixture, AB Ring ASSY AB Welding Fixture, Seat ASSY Welding Fixture, Front Seat Cross Member Welding Fixture, Front End ASSY Welding Fixture, Dash Panel ASSY Welding Fixture, Cowl ASSY Welding Fixture uye Rocker ASSY Welding Fixture mugadziri, dhizaini kambani uye fekitori.

ISO Management System Yekugadzira Welding Fixture

Yedu Welding Fixture Team

Zvatiri Zvakanakira

1.Rich ruzivo mukugadzira otomatiki uye manejimendi manejimendi.

2.One Stop Service for stamping tool, checking fixture, welding fixtures uye masero kuti awane nguva uye kuchengetedza mari, kutaurirana nyore, kuwedzera purofiti yevatengi.

3.Professional engineering timu yekupedzisa GD&T pakati pechikamu chimwe chete nechikamu chegungano.

4.Turnkey Solution Service-Stamping Tool, Kutarisa Fixture, Welding Fixtures uye Masero ane rimwe boka.

5.Kugona kwakasimba nerutsigiro rwepasi rose uye kudyidzana kwekudyidzana.

6.Kugona kukuru: Kutarisa Fixture, 1500 seti / gore; Welding Fixture uye Masero, 400-600 seti / gore;Stamping Zvishandiso, 200-300 seti / gore.

Tine vashandi vanopfuura 352, 80% avo vari vakuru tekinoroji mainjiniya.Tooling division: 130 vashandi, Welding fixture division:60 vashandi, Kutarisa fixture division:162 vashandi, Tine nyanzvi yekutengesa & project management team, refu-refu sevhisi mhiri kwemakungwa mapurojekiti, kubva kuRFQ kusvika kugadzira, kutumira, mushure mekutengesa, timu yedu. inogona kubata matambudziko ese kune vatengi vedu muChinese, Chirungu neGerman Mutauro.

Maprojekiti Makuru Chiitiko cheWelding Masero uye Welding Fixtures

| Yakakura Welding Fixtures Project (2019-2021) | |||||

| Item | Tsanangudzo | Type | Project Name | Uhu (Sets) | Gore |

| 1 | CCB WF | Arc Welding | VW MEB31 | 60 | 2019-2021 |

| 2 | CCB WF | Arc Welding | VW MEB41 | 10 | 2020 |

| 3 | CCB WF | Arc Welding | VW 316 | 4 | 2020 |

| 4 | CCB WF | Arc Welding | Ford T6 | 8 | 2021 |

| 5 | CCB WF | Arc Welding | ISUZU RG06 | 3 | 2020 |

| 6 | CCB WF | Arc Welding | Bcar, BSUV | 6 | 2020 |

| 7 | CCB WF | Arc Welding | Bcar,BCAR | 7 | 2020 |

| 8 | Floor Pan WF | Sopt Welding | SK326/0RU_K Karoq RU | 15 | 2019 |

| VW316/5RU_K Tarek RU (19003) | |||||

| 9 | WS Spring Link WF | Arc Welding | WL/WS | 4 | 2019 |

| 10 | Crossmember Mabhureki WF | Arc Welding | WL/WS | 12 | 2019-2021 |

| 11 | Front Bumper WF | Arc Welding | VW281 | 14 | 2019 |

| 12 | Chassis WF | Arc Welding | ISUSU RG06 | 18 | 2019 |

| 13 | SL ASY uye MBR uye EXT ASY | Spot uye Arc Welding | Ford P703 | 25 | 2019-2021 |

| 14 | CCB WF uye Wroking Cell | Arc Welding | ISUSU RG06 | 6 | 2020 |

| 15 | Front Seat Cross Member WF | Sopt Welding | Volkswagen AG MEB316(20001) | 4 | 2020 |

| 16 | Floor Pan WF uye Grippers | Sopt Welding | AUDI/ PORSCHE PPE 41(19017 Phase 1) | 18 | 2020 |

| 17 | Wheel House WF uye Grippers | Arc Welding | Ford BX755(19018) | 6 | 2020 |

| 18 | AB Mhete WF uye Grippers | Arc Welding | Ford BX755(19018) | 14 | 2020 |

| 19 | Dash Panel WF uye Grippers | Sopt Welding | South Africa Ford T6(17028-1) | 10 | 2020 |

| 20 | Cowl WF uye Grippers | Spot Welding | South Africa Ford T6(17028-3) | 6 | 2020 |

| 21 | Front End WF uye Grippers | Spot uye Arc Welding | South Africa Ford T6(17025) | 10 | 2020 |

| 22 | Rocker WF uye Grippers | Spot Welding | South Africa Ford T6(19029) | 8 | 2020 |

| 23 | Floor Pan WF uye Grippers | Sopt Welding | AUDI/ PORSCHE PPE 41(19017 Phase 2) | 63 | 2021 |

| 24 | Rear Bumper uye Chassis WF | Arc Welding | Ford P703&J73 | 36 | 2020-2021 |

| Yakakura Welding Fixtures Project (2022) | |||||

| Item | Tsanangudzo | Type | Project Name | Uhu (Sets) | Gore |

| 25 | Middle Channel Reinforcement WF | Sopt Welding | Vinfast VF36 | 8 | 2022 |

| 26 | Floor Pan WF uye Grippers | Sopt Welding | AUDI/ PORSCHE PPE 41(19017 Phase 3&4) | 39 | 2022 |

| 27 | Floor Pan WF | Sopt Welding uye Projection Welding | Ford P703 PHEV | 29 | 2022 |

| 28 | Floor Pan WF uye Grippers | Sopt Welding | Porsche E4 Floor Pan(21050) | 16 | 2022 |

| 29 | Floor Tunnel WF | Laser kumaka | VW Floor Tunnel(21008) | 2 | 2022 |

| 30 | Seat ASSY WF uye Tooling | Arc Welding | BYD Seat ASSY | 40 | 2022 |

| 31 | Floor Pan WF | Spot uye Arc Welding | Ford Refurbishment | 24 | 2022 |

| 32 | CCB WF | Arc Welding | VW Cyclone CCB(21037) | 10 | 2022 |

| 33 | CCB WF | Arc Welding | VW MQB37(22022) | 16 | 2022 |

| 34 | A&B-Mbiru WF | Spot Welding | Gestamp GS2203 | 8 | 2022 |

| 35 | Robot Cell Base | NA | VW Cyclone | 4 | 2022 |

Welding Fixture Manufacturing Center

Isu tinokwanisa kuvaka marudzi ese akasiyana saizi welding fixture kusanganisira yakakura saizi sezvo isu tine hombe CNC Machina.Nemhando dzakasiyana-siyana dzemichina dzakadai sekugaya, kugaya, michina yekucheka waya uye michina yekuchera, tinogona kunyatso kudzora maitiro ekugadzirisa.

25 seti yeCNC ine 2 shift inomhanya

1 Seti ye3-Axis CNC 3000*2000*1500

1 Seti ye3-Axis CNC 3000*2300*900

1 Seti ye3-Axis CNC 4000*2400*900

1 Seti ye3-Axis CNC 4000*2400*1000

1 Seti ye3-Axis CNC 6000*3000*1200

4 Seti ye3-Axis CNC 800*500*530

9 Seti ye3-Axis CNC 900*600*600

5 Seti ye3-Axis CNC 1100*800*500

1 Seti ye3-Axis CNC 1300*700*650

1 Seti ye3-Axis CNC 2500*1100*800

5 Axis CNC -Muchina

4 Axis CNC -Muchina

Welding Fixture Gungano Center

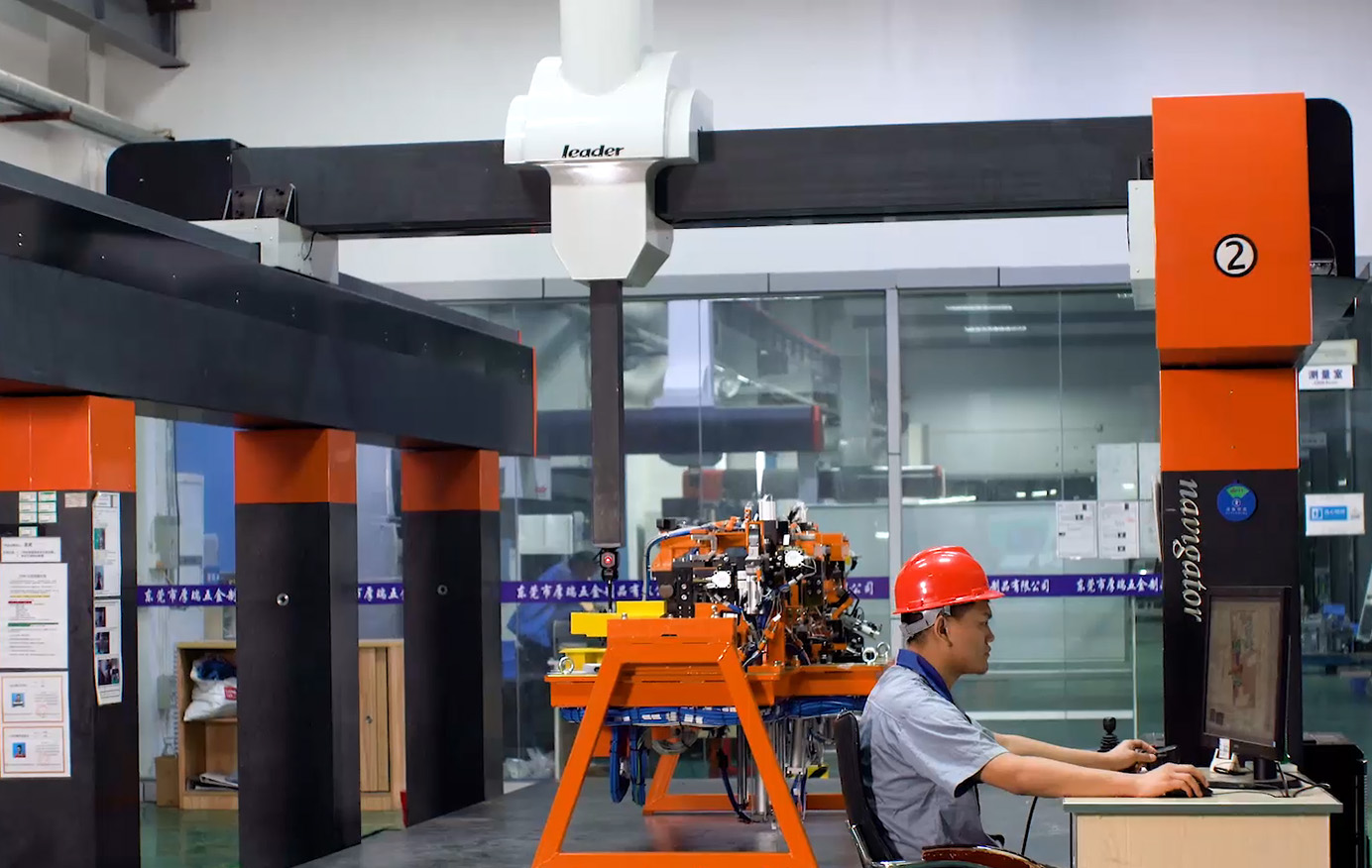

CMM Measurement Center Yekugadzirisa Welding Fixture

Our akanaka akadzidziswa vashandi vanozochengeta nguva dzese muchirongwa chese chatinacho.Tinogona kuita zvese zvinodiwa kubva kumutengi, kuve nekugutsikana kukuru muCMM zvakare.

3 Seti dzeCMM, 2 Shifts/Zuva(10hrs per shift Mon-Sat)

CMM, 3000*1500*1000 , Mutungamiri CMM, 1200*600*600 , Mutungamiriri Bhuruu-chiedza Scanner

CMM, 500*500*400, Hexagon 2D Projector, Hardness Tester

.png)

.png)