TTM Group ikambani inokwanisa kugadzira mota otomatiki welding michina.Zvigadzirwa zvedu zvinoshandiswa zvakanyanya mumunda wekugadzira mota, uye zvinovimbwa zvakanyanya uye zvinorumbidzwa nevatengi.Zvigadzirwa zvedu zvemotokari otomatiki welding zvinonyanya zvinosanganisira marobhoti welding masisitimu, laser welding midziyo, gasi shielded welding michina, nezvimwe. Zvigadzirwa izvi zvese zvakagadzirirwa uye zvinogadzirwa nechikwata chedu chehunyanzvi, chinoratidzira kugona kwakanyanya, kugadzikana uye kuchengeteka.

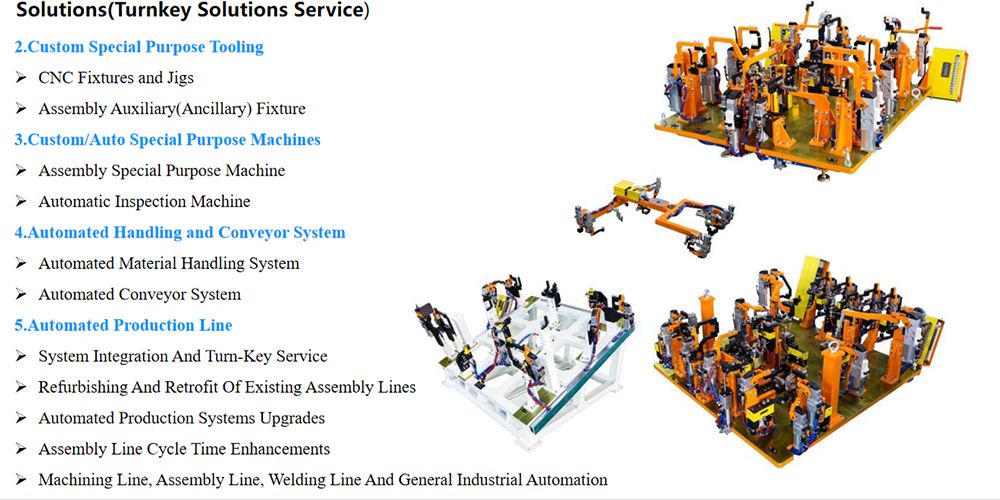

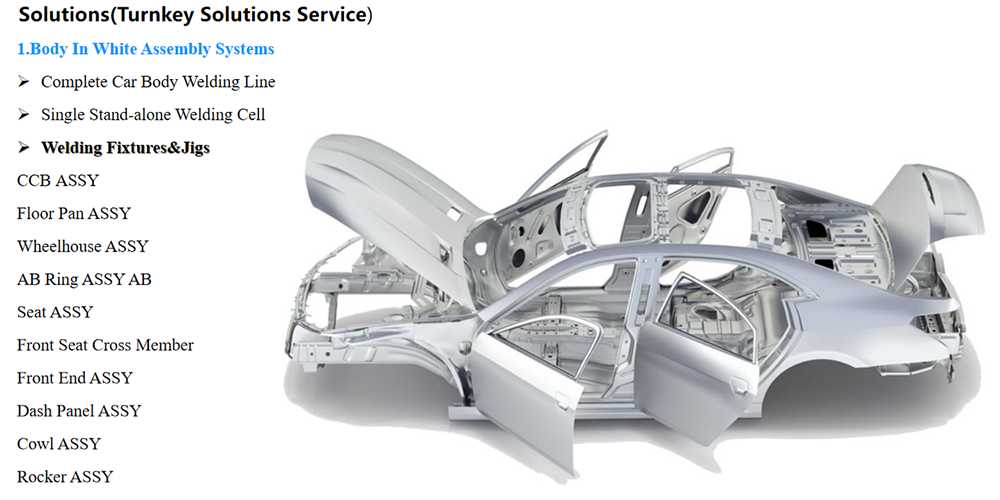

Sezvo chimiro chemotokari chakanyanya kuomarara kupfuura icho chezvakajairwa zvigadzirwa zvemuchina, kuungana uye welding process yakaoma, uye huwandu hwekugadzira hwakakura, kunyanya kugadzira kwemuviri wemotokari kwagara kuri indasitiri ine yakanyanya kukwirisa-tech-tech application.Kiyi iri kunyanya nemarobhoti makuru ekuwelda uye macalculator.Muviri welding wekugadzira mutsara unoumbwa neyepamberi otomatiki marasha ekurodha michina.

Yakawanda yemuviri wemotokari inoumbwa nesimbi inoumbwa uye inovhara zvikamu, uye dzakasiyana-siyana pre-yakajairwa zvimiro zvemukati, senge mbiru dzemhepo, mbiru dzegonhi, masuo ekumusoro njanji, kumberi nekumashure mafenda, kumberi nekumashure mapaneru, mavhavha epamusoro, nezvimwe. inounganidzwa newelding uye riveting, pakati peiyo welding inhanho yakakosha mumutsara wekugadzira mota.

Mumakore achangopfuura, vagadziri vemotokari vakakura vakagamuchira mitsetse yewelding yemarobhoti, uye vakati wandei vakaratidza kusimba kwehunyanzvi hwepasirese.Pakati pemarobhoti aya, marobhoti welding anoverengera chikamu chakakura.

Mumakore achangopfuura, iyo laser welding body tekinoroji yakatsiva zvishoma nezvishoma tekinoroji yekumisa welding tekinoroji, iyo inogona kuzadzisa zvakakwana zvinodiwa mukugadziriswa kwezvikamu zvemotokari.Uchishandisa iyi tekinoroji nyowani, iyo yakabatana pamusoro pehupamhi pakati pekubatanidza workpiece inogona kuderedzwa, iyo isingangodzikisi kudiwa kwemaplate Inowedzerawo kuomarara kwemuviri.Laser welding parts, hapana chakanyanya kukanganiswa muzvikamu zvewelding zvezvikamu, kumhanya kwewelding kunokurumidza, uye hapana chikonzero chekurapa kwekupisa kwemashure.Laser welding ine mukana wakanaka maererano nekushanda zvakanaka, hupfumi, chengetedzo, simba, uye kusagadzikana kwekuora.Uye iyi tekinoroji nyowani yavewo makina makuru nemidziyo muindasitiri yekugadzira maindasitiri.

Yedu mota otomatiki welding zvigadzirwa zvakashandiswa zvakanyanya mumabhizinesi mazhinji ekugadzira mota kubatsira vatengi kuona kugadzira otomatiki, kunatsiridza kugadzirwa kwakanaka uye mhando, uye kugadzira kukosha kukuru kune vatengi.Ticharamba tichisimudzira hunyanzvi hwekuvandudza tekinoroji uye tsvakiridzo yezvigadzirwa nekusimudzira, kupa vatengi zvigadzirwa nemasevhisi zviri nani, uye nekubatsira kusimudzira indasitiri yemotokari.

Nguva yekutumira: Kubvumbi-28-2023

.png)

.png)