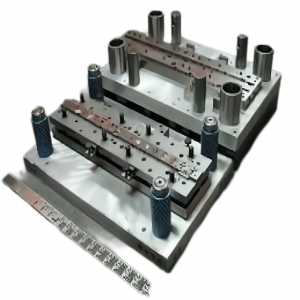

Welding Fixture YeMuchinjikwa Nhengo WS Spring Link

Vhidhiyo

Minda Yekushandisa

Automotive industry quality control

Mota yekugadzira mutsara wekugadzira kugona kunovandudza

Tsanangudzo

| Fixture Type: | Arc Welding |

| Saizi | 1800x1300x900mm |

| Kurema | 125KG |

| Material: | Main Kuvaka: simbi Kutsigira: simbi |

| Surface treatment: | Base Plate: Electroplating Chromium uye Black Anodized |

Product Details

Detailed Sumo

Iri ndiro batch of welding fixture yeWL Cross Member WS Spring Link, zvakazara mumaseti maviri, takagadzirira mutengi wedu weCanada.Chitubu chuck shank chigadziriso checylindrical chakaiswa mumushini wekugaya kuti uvharise chibhorani kana chigayo chekucheka.Pinza chuck mukati mekiyi nati uye zvinyoro nyoro ukuruna nati yekiyi nespring chuck pashank, connector kana spindle.Zvichienderana nekusimba kwesimbi elastic kuomesa, yakasununguka clamp iri nyore, inonyanya kushandiswa kurovedzera mwenje, yepakati mitoro yekucheka maturusi.Inowanzo shandiswa kusungirira maturusi ekucheka akadai semaguyo ekupedzisira, zvibooreso, matepi, reamers uye pakati drills.Shandura clamping range nekuchinja zvakasiyana-siyana zvinounganidzwa. Kana uchisunga, chikamu cheshinda chechirimo chechuck, lock nut uye positioning surface uye cone surface inofanira kucheneswa.Panguva yekumisikidzwa kwechuck nekiyi nati, chuck nekiyi nati zvinofanirwa kurerekera kune imwe Angle yozoiswa mukiyi yekiyi nati.Usashandise iyo yakawedzera simba wrench torque yakanyanya kusimba, kudzivirira meteorite yakaipa chishandiso uye chigadziriso.

Kufamba Kwekushanda

1. Akagamuchira odha yekutenga-——->2. Dhizaini-——->3. Kusimbisa kudhirowa / mhinduro-——->4. Gadzirira zvinhu-——->5. CNC-——->6. CMM-——->6. Kuungana-——->7. CMM-> 8. Kuongorora-——->9. (Chikamu chechitatu chekuongorora kana zvichidiwa)-——->10. (yemukati/mutengi panzvimbo)-——->11. Kurongedza(bhokisi remapuranga)-——->12. Delivery

Manufacturing Tolerance

1. The Flatness yeBase Plate 0.05/1000

2. Hukobvu hweBase Plate ±0.05mm

3. Nzvimbo Datum ± 0.02mm

4. The Surface ± 0.1mm

5. Mapini ekutarisa nemakomba ± 0.05mm

Process

CNC Machining(Kugaya/Kutendeuka), Kukuya

Electroplating Chromium uye Black Anodized Kurapa

Maawa ekugadzira (h): 40h

Kuvaka Maawa (h): 150h

Quality Control

CMM (3D Coordinate Measuring Machine), Vms-2515G 2D Projector, HR-150 A Hardness Tester

Chechitatu Bato Chitupa chakaitwa neShenzhen Silver Basis Testing Technology Co., Ltd, ISO17025 Certified

.png)

.png)