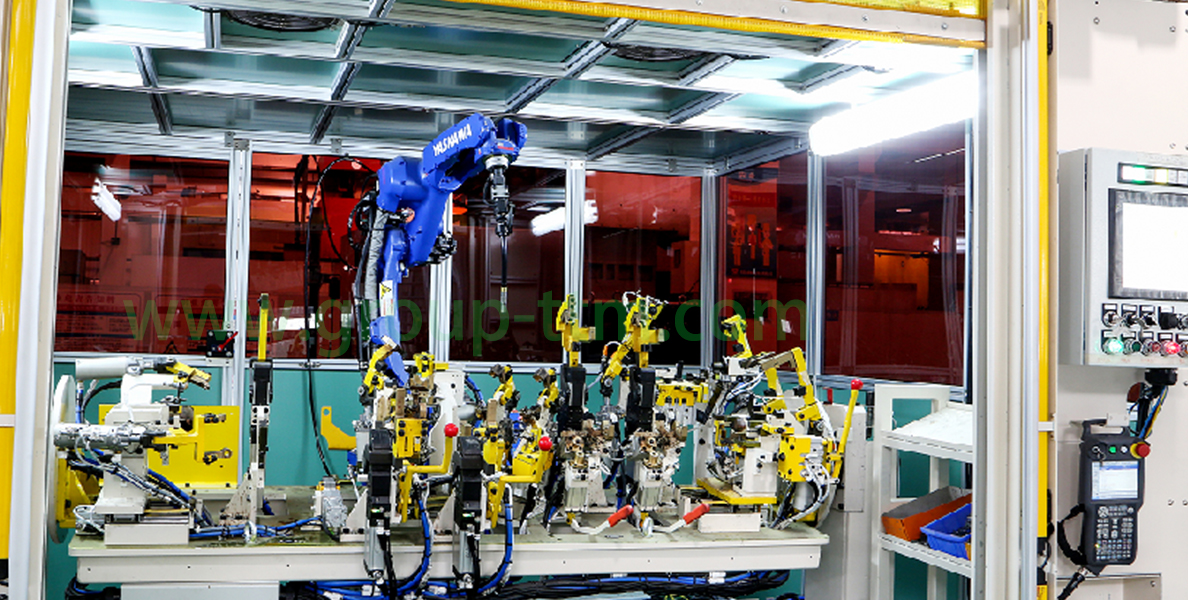

Mukugadzirwa kwemaindasitiri, kuitira kuti tive nechokwadi chekurongeka kwewelding, isu kazhinji tinoda kushandisawelding zvigadziriso.Saizvozvo, kugadzirwa kwemotokari kunodawo kushandiswa kwemota welding zvigadzirisokudzivirira welding deformation.Saka ndeipi basa reiyo mota welding fixture?

1. Basa rinorema rekuisa, clamping uye workpiece kutendeuka kana manually kuunganidza zvikamu zvinotsiviwa nemichina michina, iyo inovandudza mamiriro ekushanda evashandi.

2. Kumisikidza kwakaringana uye kwakavimbika uye kusungirira kunogona kuderedza kana kudzima basa rekumaka.Dimensional kutsauka kwechigadzirwa kunoderedzwa, uye kurongeka uye kutsiva kwezvikamu kunovandudzwa.

3. Chengetedza workpiece munzvimbo yakanakisa yewelding, kuumbwa kweiyo weld seam yakanaka, kukanganisa kwemaitiro kwakaderedzwa zviri pachena, uye kukurumidza kwewelding kunovandudzwa.

4. Inogona kuunza hupfumi hukuru kukambani, uye mutengo \ nguva yezvishandiso zvakakosha zvakaiswa mune yega yega shanduko shanduko inogona kunge isingachashandiswe.Chishandiso chacho chiri nyore kushandisa uye chakachengeteka kushandisa, uye vashandisi vanogona kukurumidza kupatsanura maturusi nezvinodiwa zvakasiyana zvinoenderana nezvavanoda.

5. Zvigadziriso zvemotokari zvinogona kuwedzera chiyero chekushandiswa kwehunyanzvi hwekuita tekinoroji uye kusimudzira budiriro yakazara yemakanika uye otomatiki yewelded chimiro kugadzirwa.

6. Kuita kwakanyatsogadzikana.Kana zvikamu zvakakanganiswa nekuda kwekushandisa zvisina kunaka, hapana chikonzero chekurasa tafura yose, uye chikamu chimwe chete chinogona kutsiviwa nemari shoma.

7. Motokari welding zvigadziriso zvinogona kudzivirira zvinobudirira uye kuderedza welding deformation.

Naizvozvo, zvigadziriso zvemotokari welding zvinoita basa rakakosha mukugadzira nekugadzira mota.

Nguva yekutumira: Jun-23-2023

.png)

.png)